Menu

Inofast Manufacturing maintains a diverse array of CNC machining centers as well as manual tools to produce our high-quality parts. Among our machines are traditional 2 and 4-axis lathes, lathes with integrated live tooling, an 8-axis combination mill/turn machine, and a high-horsepower lathe with an extra-large machining envelope.

Inofast Manufacturing maintains a diverse array of CNC machining centers as well as manual tools to produce our high-quality parts. Among our machines are traditional 2 and 4-axis lathes, lathes with integrated live tooling, an 8-axis combination mill/turn machine, and a high-horsepower lathe with an extra-large machining envelope.

Our machines are operated by a team of experienced and quality-conscious operators, skilled at holding tight-tolerances in the toughest of materials. Machining code is produced by a combination of talented CAD/CAM programmers and sophisticated automation software to minimize geometry errors.

We are able to produce both cut and rolled threads in virtually any standard or custom series.

In addition to our in-house capabilities, Inofast Manufacturing works with a large network of local and national subcontractors. These subcontractors primarily handle our post-machining process needs. Common processes include heat treating, plating or coating, grinding, nylon locking, welding, and more. All subcontracted processes are performed in accordance with the procedures required by your specification. We collect and verify all certification documents from these specialists and include them with our final document package.

In-House Equipment

Okuma Cadet-Mate Mill

- 3-Axis Vertical Mill

- Tsudakoma Programmable Indexer

- Automatic Tool Changer (20 Tools)

Okuma MC-4VA Mill

Okuma MC-4VA Mill

- 3-Axis Vertical Mill

- Tsudakoma Programmable Indexer

- Geared mill for high torque to allow machining exotic material

Okuma Captain L370 Lathe

- 2-Axis Lathe

- 20” Max Diameter

- 20” Max Length Between Centers

Okuma LU-300M Lathe

- 4-Axis Lathe

- Live Tooling

- 20” Max Diameter “Big Bore”

- 20” Max Length Between Centers

- LNS Hydraulic Bar Feeder

Okuma LB-25 II Lathe

- 2-Axis Lathe

- 20” Max Diameter

- 20” Max Length Between Centers

- LNS Hydraulic Bar Feeder

Okuma LU 35 Impact Lathe

Okuma LU 35 Impact Lathe

- 4-Axis

- 29” Max Diameter

- 60” Max Length (2200# max between centers)

- 4 speed gear box for high torque

- LNS Hydraulic steady/follow rest (resident on top turret)

Dainichi F20 Lathe

Dainichi F20 Lathe

- 2-Axis

- 15” Max Diameter

- 20” Max Length Between Centers

Okuma LB-15 Lathe

- 2-Axis

- 10” Max Diameter

- 25” Max Length Between Centers

- LNS Hydraulic Bar Feeder

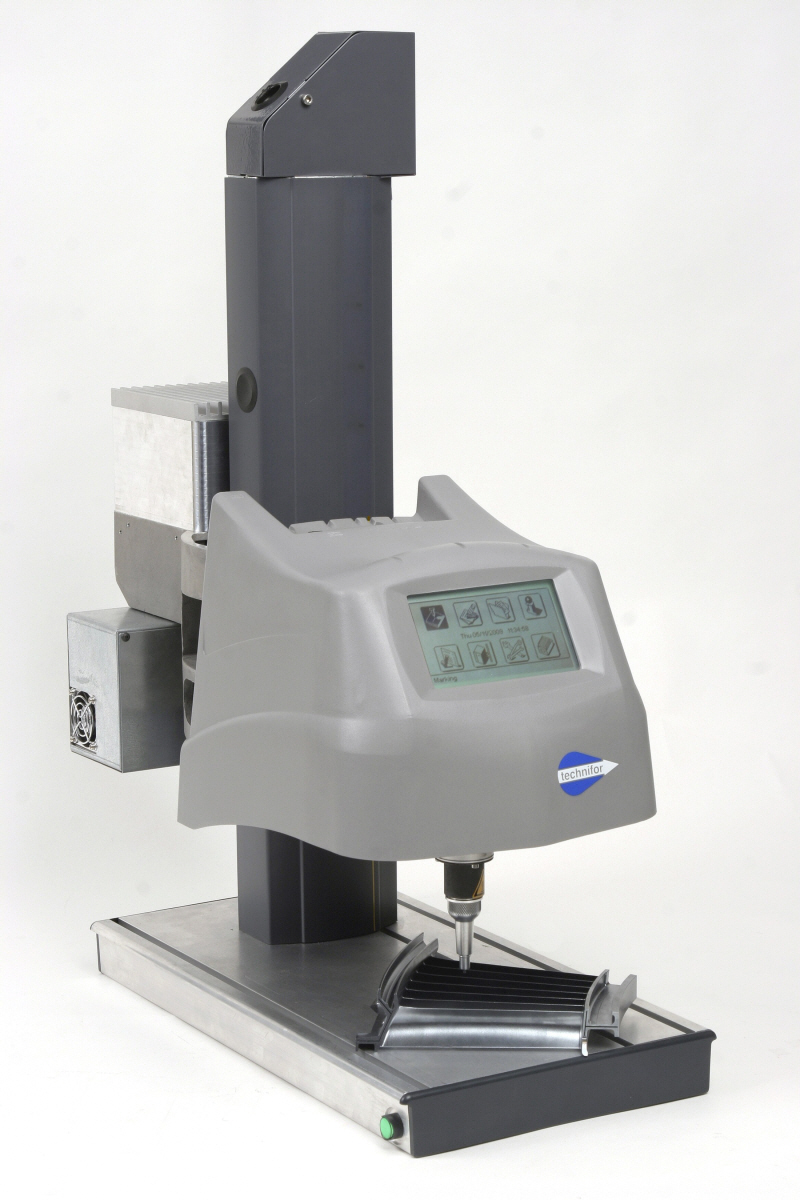

Technifor Micro-Percussion Etching Machines

Technifor Micro-Percussion Etching Machines

- CNC Controlled

- Diamond Tips

- Cylindrical marking available

Landis Thread Cutters (2)

Landis Thread Cutters (2)

- Tangential Die Head

- 0.440” Min to 7/8” Nominal Thread Max.

- 5/16” Min to 1-1/2” Nominal Thread Max.